-

SEARCH

Type your search in the field above

Potential, negative and positive effects on the economy, environment and people

Climate change refers to the long term changes in the Earth’s climate system, including, changes in temperature, precipitation, and weather patterns, that are primarily caused by human activity.

Climate changes can cause several negative impacts such as:

Rising sea levels: As global temperature rise, glaciers and ice sheets melt, and sea levels rise. This could lead to flooding of low-lying areas and displacement of millions of people.

Extreme weather events: Climate change leads to more frequent and severe weather events, including hurricanes, droughts, heatwaves, and wildfires. These events can cause significant damage to infrastructure, homes, and ecosystems.

Loss of biodiversity: As temperatures rise, many species may be unable to adapt to changing conditions and may go extinct. This could have cascading effects on ecosystem and food chains.

Water scarcity: Climate change is expected to lead to more frequent and severe droughts, which could lead to water scarcity in many regions. This can potentially cause conflicts over water resources and harm agriculture and food production.

Health impacts: Climate change could lead to increased incidence of several diseases. This could have significant impacts on public health and healthcare systems.

Economic impacts: Climate change could lead to significant economic impacts, including damage to infrastructure, lost productivity, and higher costs for disaster relief. These impacts could be particularly severe for low-income communities and developing countries.

2024 was confirmed as the warmest calendar year on record (records going back to 1850). According to NASA, the average global surface temperature in 2024 was above the 20th century base-line. The World Meteorological Organization (WMO) also reported that 2024's global average surface temperature was about 1.55 degrees Celsius above the pre-industrial level. This marks the first calendar year with a global mean temperature exceeding 1.5 degrees Celsius above the 1850-1900 average. The urgency to take decisive climate action has never been greater.

Lerøy, is aware of its duty to contribute to taking climate action by reducing its emissions of carbon dioxide and other greenhouse gases (GHG).

The Group emits GHG through its operations. Lerøy is performing GHG reporting (Scope 1, 2 and 3) to monitor and control its own and relevant supply chain emissions in order to be able to take appropriate measures for reducing the its GHG emissions.

The Group also implicitly contributes to deforestation by purchasing fish feed. Lerøy is working proactively with its business partners (including fish feed suppliers) to develop alternative fish feed ingredients. Lerøy has entered a strategic partnership agreement with a fish feed supplier. A strategic partnership agreement ensures that we collaborate with a partner that has also set ambitious targets regarding reduction of GHG emissions.

Lerøy generates waste, including plastic waste, however it is taking appropriate steps to reduce its contribution to waste pollution (for more detailed information regarding waste pollution, please, visit section Water and Waste Management (Environment) in Lerøy Sustainability library 2024.

Lerøy has developed Climate and Energy Consumption Policy which sets out a range of actions and measures aimed at addressing climate change and introducing sustainable business practices. The goal of the policy is to mitigate the negative impacts of climate change and reduce risks associated with it.

Actions taken to manage the topic and related impacts:

Lerøy is continuously working on improving its monitoring and reporting of greenhouse gas emissions. Information regarding our greenhouse gas emissions is crucial for understanding and responding to environmental challenges as well as to being able to identify improvement opportunities.

2024 was the first year Lerøy reported according to Corporate Sustainability Reporting Directive (CSRD). The Group's Scope 3 accounting was updated considerably ensuring compliance with the requirements in CSRD as well as completeness fo all reporting categories. This is a major change which contributes to much higher GHG-emissions compared to the original 2019-levels. This is a complex area and, in coming years, the Group will continue to work on improving data quality, particularly within the category Purchased Goods and Services.

The Group’s toltal Scope 1, 2 and 3 GHG emissions in 2024 have decreased with 0,6% (12 174 tCO2e) compared to 2023 levels.

Scope 1 emissions have decreased with 7% compared with 2023 levels.

Scope 2 emissions have decreased with 7% compared with 2023 levels.

Scope 3 emissions have increased with 1% compared with 2023 levels.

Science Based Targets

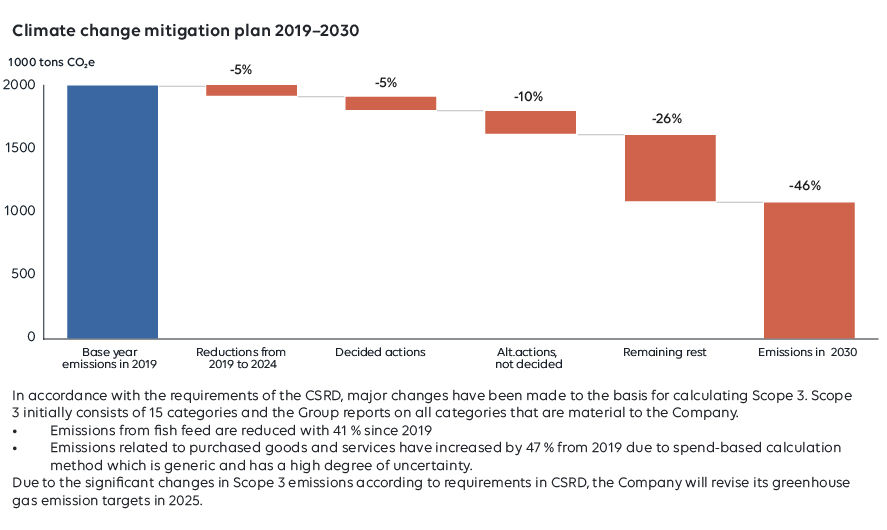

Lerøy Seafood Group has committed to a science-based target which is aligned with the climate targets of the Paris Agreement (2015). The Group aims to achieve a 46% GHG emission reduction (Scope 1+2+3) by 2030, with a 2019 base-year (the 1,5 degree pathway). The science-based target was reviewed and approved by the Science Based Targets initiative (SBTi), with approval date 9th April 2021. This is a fixed (absolute) reduction target that does not change with the Group's growth or changes in production levels, meaning that even if the Group expands its operations, it must still achieve the same total reduction in emissions.

In 2024 Lerøy has reduced its overall Scope 1, 2 and 3 emissions with 4,7% from 2019 levels.

The implementation of CSRD has led to significant changes in GHG calculations for both the base year (2019) and recent reporting year (2024). Lerøy has commenced working on updating its Industry & Energy science-based target as well as setting its Forest, Land and Aquaculture (FLAG) target.

Lerøy has an ambition to become climate neutral by 2050.

The reported emission figures have been collected throughout 2024 both internally and from relevant external suppliers.

Lerøy’s GHG emissions are reported in accordance with the GHG Protocol Corporate Accounting and Reporting Standard. The Group uses operational control approach for consolidating its GHG emissions accounting. It means that emissions from operations, over which Lerøy have operational control, are included in Scope 1 and 2 reporting. Indirect upstream and downstream emissions relating to its operations are accounted for in Scope 3. Reporting units account for their use of fossil fuels, refrigerants, electricity, district heating/cooling, water usage, waste composition (incl. methods of waste disposal).

Climate account statements are consolidated in the same manner as financial statements showing aggregated results for the Group’s entities (reporting units).

The Group’s Scope 3 emissions are reported in accordance with the GHG Protocol Corporate Accounting and Reporting Standard (Corporate Value Chain (Scope 3)). For more detailed information, please, see table Scope 3 Overview per Category below.

Emission factors

Emissions data for Scopes 1, 2 and 3 cover reporting of the following greenhouse gases: carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O), hydrofluorocarbons (HFCs), perfluorocarbons (PFCs) and HFO (hydrofluro-olefins). There are seven main GHGs that contribute to climate change, as covered by the Kyoto Protocol: carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O), hydrofluorocarbons (HFCs), perfluorocarbons (PFCs), sulphur hexafluoride (SF6) and nitrogen trifluoride (NF3).

The Group has had 7 270 tCO2e biogenic CO2 emissions in Scope 1.

Biogenic emissions are CO2 emissions related to the natural carbon cycle, as well as those resulting from the combustion, harvest, digestion, fermentation, decomposition, or processing of biologically based materials.

Scope 1

Sources for Scope 1 emission factors used for calculation of tCO2e are DEFRA (Department for Environmental Food and Rural Affairs, UK Government), 2024, US Environmental Protection Agency (2024), Norwegian Environmental Agency (2023), Linde Gas (2019; 2022; 2024), Honeywell Refrigerants (2014), A-gas (2024).

Scope 2

There are two types of Scope 2 emissions: location-based, and market-based. Location-based Scope 2 emissions are calculated based on the average emissions factor for the grid region where the organisation consumes electricity. Market-based Scope 2 emissions, on the other hand, take into account the specific contractual instruments that an organisation has in place to purchase renewable energy certificates or power purchase agreements.

Sources for Scope 2 emission factors used for calculation of tCO2e are: International Energy Agency (2024), Foreløbig national deklarering af 1 kWh el, 2022 (Energinet, 2023), Generelle eldeklaration 2022 (Energinet, 2023) (Denmark), Norwegian Water Resources and Energy Directorate (NVE) (2024), Fjernkontrollen (2024), Energistyrelsen (2024), Finnish Energy (2024).

Guarantees of Origin (GOs)

The Group has purchased Guarantees of Origin (GOs) in 2024. Information regarding companies which have purchased GOs as well as the percentage share that covers the consumption is reported in Cemasys (the Group’s internal reporting system for GHG emissions accounting).

Regarding market-based emissions – the choice of emission factor using this method is determined by whether the business acquires GOs or not. For electricity without the GOs, the emission factor is based on the remaining electricity production after all GOs for renewable energy are sold. This is residual mix, which is normally substantially higher than the location-based factor.

Scope 3

Sources for Scope 3 emission factors used for calculation of tCO2e are: DEFRA (2024), Års- og bærekraftsrapport 2023 for Vygruppen, study "Investigating the impact of e-bikes on modal share and GHG" (2019), VR Group Annual Report 2023, Avg energy consumption (Norsk elbilforening), Ruter 2023 Miljorapportering and IEA (2024), Ecoinvent 3.11, Greenhouse gas emissions of Norwegian seafood products in 2017. SINTEF study, based on EPD, US Environmental Protection Agency (2024), Information from fish feed and plastic products suppliers.

The categories included in the table are accounted for in the Group’s Scope 3 reporting. The Group does not have downstream leased assets or franchises. The Group also evaluates that use of sold products is not relevant to the Group’s reporting as “sold products” in our context is food which is consumed by the customers.

Scope 1, 2 and 3 GHG Emissions 2024 (incl. % change comparing to base year (2019) and comperative year (2023))

| Base year (2019) | Comperative year (2023) | Recent year (2024) | % change vs base year | % change vs recent year | |

| SCOPE 1 | |||||

| Gross Scope 1 GHG emissions (tCO2e) | 160 138 | 168 064 | 156 638 | -2,19 | -6,8 |

| SCOPE 2 | |||||

| Gross location-based Scope 2 GHG emissions (tCO2e) | 5 917 | 8 821 | 8210 | 38,74 | -6,93 |

| Gross market-based Scope 2 GHG emissions (tCO2e) | 44 685 | 86 428 | 103 036 | 130,59 | 19,22 |

| SCOPE 3 | |||||

| Total gross indirect (Scope 3) GHG emissions (tCO2e) | 1 816 966 | 1 704 628 | 1 728 841 | -4,9 | 1,42 |

| Purchased goods and services(tCO2e) | 1 095 153 | 1 094 207 | 956 393 | -12,7 | -12,59 |

| Capital goods (tCO2e) | 27 046 | 34 443 | 36 376 | 34,5 | 5,61 |

| Fuel and energy related activities (tCO2e) | 36 726 | 42 818 | 39 522 | 7,6 | -7,70 |

| Upstream transportation and distribution (tCO2e) | 543 935 | 421 293 | 533 618 | -1,9 | 26,66 |

| Waste generated in operation (tCO2e) | 3 061 | 3 583 | 4 596 | 50,1 | 28,27 |

| Business travel (tCO2e) | 633 | 1 518 | 798 | 25,9 | -47,48 |

| Employee commuting (tCO2e) | 6 186 | 6 803 | 7 396 | 19,6 | 8,72 |

| Downstream transportation and distribution (tCO2e) | 7 564 | 4 540 | 5 536 | -26,8 | 21,92 |

| Processing of sold products (tCO2e) | 18 488 | 19 566 | 22 102 | 19,5 | 12,96 |

| End of life treatment of products (tCO2e) | 1 882 | 1 886 | 1 644 | -12,7 | -12,82 |

| Investments (tCO2e) | 76 292 | 73 972 | 120 845 | 58,4 | 63,37 |

| Total Scope 1+2+3 (location-based) (tCO2e) | 1 983 021 | 1 881 513 | 1 893 688 | -4,7 | 0,65 |

| Total Scope 1+2+3 (market-based)(tCO2e) | 2 021 788 | 1 959 120 | 1 985 340 | -1,8 | 1,34 |

Scope 1 & 2 GHG emissions per opearating segment

| Operating segment | Scope 1 (tCO2e) | Scope 2 (location-based) (tCO2e) | Scope 2 (market-based) (tCO2e) |

| Farming | 51 588 | 2 369 | 66 956 |

| Wild catch | 102 811 | 373 | 14 888 |

| VAP, Sales & Distribution | 2 239 | 5 268 | 18 018 |

| Total | 156 638 | 8 010 | 99 862 |

| Category | tCO2e | |

|---|---|---|

Purchased goods and services

tCO2e

This category is comprised of two parts: emissions data regarding purchased goods and services, where the information is collected directly from relevant suppliers, and emissions data calculated using the spend-based calculation method, which is generic and embeds a high degree of uncertainty. Data on fish feed carbon intensity is collected from relevant fish feed suppliers. The calculated GHG emissions for purchased fish feed also include transportation emissions, relevant Scope 3 emissions, and emissions related to land use change (LUC), calculated using the economic allocation method. EPS boxes (Styrofoam boxes with lids): Information regarding EPS boxes (number, type, properties) is collected from the Group’s companies throughout the year. Plastic bags/sheets and single-use hygiene plastic items: Information regarding plastic bags/sheets and single-use hygiene plastic items is collected from the Group’s companies throughout the year. Vacuum packaging/film: Information regarding vacuum packaging/film is collected from the Group’s companies throughout the year. Cardboard/carton boxes: Information regarding cardboard/carton boxes is collected from the Group’s companies throughout the year. Rope and feeding tubes: Information regarding rope and feeding tubes is collected from the Group’s companies throughout the year. Municipal water: Information regarding consumed municipal water is collected from the Group's companies throughout the year. Rest of purchased goods and services: Consumption information is derived from financial statements, and emissions are calculated using the spend-based method. |

||

Capital goods

tCO2e

Information derived from financial statements, and emissions are calculated using the spend-based method. |

||

Fuel and energy related activities

tCO2e

Well to Tank (WTT)*. Calculations based on the existing consumption data volumes collected from the Group’s companies throughout the year. The calculation is based on the reported consumption data for Scope 1 and 2 (for more detailed information, see table Total Consumption of Fossil Fuels (Scope 1)). |

||

Upstream transportation and distribution (outbound transportation)

tCO2e

Transportation services (sea transportation, service boats, well boats**). Consumption data collected from sea transportation/ well- boat service providers (calculations include WTT). Transportation of produced products to customers. Information collected from the Group’s Logistics department. The calculations are based on distance from capital to capital. The emission factors used are determined by type of transportation mode. |

||

Waste generated in operations

tCO2e

Waste - data on waste volumes, waste composition (incl. methods of waste disposal) is collected from the Group’s companies throughout the year. |

||

Business travel

tCO2e

Air travel (business travel by air) - information regarding distances traveled is collected from travel agent the Group uses (including WTT). |

||

Employee commuting

tCO2e

Employee commuting – estimation based on SSB (Statistisk Sentralbyrå) for Norwegian operations, TRAFA (Transport Analysis) for Swedish operations, and STATISTA for operations in the Netherlands. For all other operations - INSEE statistics, ACEA (European Automobile Manufacturer’s Association) well as official government websites are used.

|

||

Upstream leased assets

N/A |

||

Downstream transportation and distribution

tCO2e

Downstream transportation and distribution - transportation of products carried out by the customers themselves. Information collected from the Group’s Logistics department. The calculations are based on distance from capital to capital. The emission factors used are determined by the mode of transportation. |

||

Processing of sold products

tCO2e

Processing of sold products – calculations consist of two parts – part one - estimated use of electricity for storage of fish in the country of consumption before the product is sold to end consumer. Part two – estimated emissions related to third party processing. |

||

Use of sold products

N/A |

||

End-of-life treatment of sold products

tCO2e

End of life treatment – organic waste estimated share (%) of non-edible fish. |

||

Downstream leased assets

N/A |

||

Franchises

N/A |

||

Investments

tCO2e

This category covers the greenhouse gas emissions associated with the Group's financial investments and is covering the Group's most significant investments |

||

*Well-to-tank (WTT) refers to the greenhouse gas (GHG) emissions that occur during the production, processing, and transportation of fuel until it is ready for use and covers the entire upstream process, from extracting raw mataerials to delivering the fuel for use in vehicles or facilities.

**Well-boats and service boats which are not classified as operating leases (ref. definition IFRS 16) are included in Scope 3 emissions since Lerøy does not have operational control over the leased assets held under an operating lease.

For more detailed information regarding the categories, please visit Corporate Value Chain (Scope 3) Accounting standard

Emissions from feed production 2024, incl. land luse

| GHG emissions from fish feed | tCO2e |

| Total GHG emissions from fish feed production 2024 | 444 929 |

| GHG emissions from fish feed from Land Use Change (LUC) | 46 963 |

GHG emissions intensity ratio per operating segment

| Operating segment | Emissions (Scope 1+2) emissions (mt) 2024 | Production volume (mt) 2024 (Farming segment - live weight equivalent) | Intensity (total GHG emissions/ total production volume) 2024 |

| Farming | 53 955 | 332 901 | 0,16 |

| Wild Catch | 103 184 | 163 591 | 0,63 |

| VAP, Sales and Distribution | 7 706 | 79 859 | 0,10 |

| Total | 164 845 | 576 350 | 0,29 |

Lerøy Seafood Group has an ambition to be the leading and most profitable global supplier of sustainable high-quality seafood. Reduction of GHG emissions is defined as one of the strategic priorities for the Group going forward. Sustainability measures are integrated into the Group’s governance and business processes. The Group has set targets for the reduction of its GHG emissions.

The Group has developed a transition plan for climate change mitigation. The plan is approved by the Group management and presented to the Board. The major element of the plan, GHG emission reduction, is embedded into the Group’s overall business strategy and aligns with its financial planning.

Any new climate change mitigation actions, as well as explanation and quantification of the Group’s investments and funding supporting the implementation of Lerøy Seafood Group's transition plan, are to be updated, reviewed and approved by the Group management and presented to the Board. Lerøy Seafood Group has allocated a budget for climate-related initiatives, such as developing emerging ingredients that contribute to more sustainable fish feed.

The Group has identified key climate change mitigation actions (decarbonisation levers) which contribute to reduction of GHG emissions and achievement of GHG emission reduction targets:

Sustainable fish feed

Fish feed is a large contributor to the Group’s Scope 3 emissions. Fish feed is GHG intensive due to its production process and raw materials which include ingredients like soybean meal, wheat and fish meal. The cultivation and harvesting of these involves substantial energy use thus generating GHG emissions. Incorporating emerging raw materials, such as by-products from European chicken production, into fish feed, represents an adaptation of new technology and increased circularity. Chicken by-products have a lower carbon footprint compared to traditional fish feed ingredients which leads to a significant GHG emission reduction. In order to reduce GHG emissions from fish feed, Lerøy Seafood Group has formed a strategic partnership with a fish feed supplier that has set goals for climate change mitigation, adaptation, and energy efficiency.

Transportation

Transportation own operations

Transportation activities in our own operations such as fishing trawlers and well- and service boats generate significant GHG emissions. There is currently no feasible technological solution for this challenge that could be a major “game changer”. The Group has increased the use of biofuel, achieving an approximately 7% reduction in its Scope 1 GHG emissions in 2024 compared to 2023 levels.Together with other actors, it also participates in various innovation programmes aimed at developing alternatives to fossil fuels (such as marine gas oil). These alternatives include conventional ammonia, blue ammonia and hydrogen.

Upstream and downstream transportation

Upstream and downstream transportation to customers is Lerøy’s second-largest contributor to generating GHG emissions. Prioritising and optimising transport weight, along with developing new technologies and reviewing alternative transportation modes, are crucial to creating more environmentally friendly transportation solutions.

Key activities include developing an internal climate calculator for air transportation to identify the most climate-friendly flight routes and reducing transportation weight by replacing conventional ice with dry ice as a cooling medium. Fresh fish is transported in EPS boxes, which can carry 20 kg of fish and approximately 5 kg of ice. By switching to dry ice, less conventional ice is needed, thereby contributing to a reduction in GHG intensity per transported EPS box of fish. The replacement of conventional ice with dry ice has been implemented in some of the Group’s packing plants.

We will reduce our greenhouse gas emissions by 46% by 2030. Lerøy has an ambition to be climate neutral by 2050.

Electrification of fleets, well boats and workboats

A large shore current system for well boats is now operational at Lerøy's Hitra facility. This investment is part of our efforts to achieve the Group's goal of reducing greenhouse gas emissions by 46% by 2030 compared to 2019 levels.

Lerøy Midt has chartered the wellboat Gåsø Høvding, designed to operate entirely on electric power for direct salmon delivery to our slaughterhouse on Jøsnøya in Hitra. The wellboat, owned by Frøy Rederi AS, has seen significant investment in its electric operation system.

With the high-voltage shore power plant investment, Lerøy Midt aims to substantially reduce nitrogen oxide (NOx) emissions and cut several thousand tonnes of CO2 equivalents annually.

The project is a close collaboration between Lerøy Midt AS as the customer, Frøy Rederi AS which owns the wellboat and Nord Trøndelag electricity utility (NTE) which has designed and built the shore power plant.

In addition to NTE and Frøy Rederi AS, Enova (Norwegian state-owned enterprise owned by the Ministry of Climate and Environment. It provides funding and advice for energy and climate projects) has been involved and taken up to 40% of the budgeted investment costs, which has made it possible to carry out the project.

Gåsø Høvding, like other well boats, is manned around the clock, so the crew in particular will be able to benefit from the silence. This will improve the working conditions and the working environment for everyone involved, both those on board and those who work at our Jøsnøya plant. In addition to the actual transport of salmon from the cages to slaughter facility, the size of the boat allows the entire biomass from a cage to be handled in one load.

The Group has established different measures in order to reduce its environmental impact; from obtaining power from land, hybrid fleets, floating solar cells, to electric working boats.

Wherever it is possible, the Group seeks to use electricity sourced from land-based powerlines instead of electricity from generators at each production site. Utilizing land-based power sources typically proves to be economically advantageous

Power from land results in:

More than 80 % of our sites now run on power from land, on remaining sites where the infrastructure is insufficient for land-based electricity, Lerøy Seafood Group is developing hybrid solutions that allow for up to 30% more efficient use of fossil fuels at each site.

Lerøy Kjærelva operates as a RAS (Recirculating Aquaculture Systems) facility, reusing 99% of its water. This minimal water usage makes it environmentally friendly and sustainable. However, RAS technology demands more electricity for water purification, resulting in a higher energy footprint for fish from RAS facilities compared to traditional farming. Nonetheless, the use of solar panels helps lower the overall carbon footprint of the facility.