-

SEARCH

Type your search in the field above

The world’s growing population will need an ever-increasing amount of food to survive. Different types of food production will always leave a footprint, so also for fisheries and fish farming.

If Lerøy's operations are not sound, this can directly affect species diversity. In the extreme, this could give our company financial fines, reduced income and a lack of capital. If we do not operate responsibly, there will be a risk that our operations may affect species diversity both in the various species we fish and in the bottom conditions where we have our farming operations. In the extreme, this can lead to reduced jobs due to a lack of fish that can be caught and locations that have to be moved or closed down.

Our ambition is to create the world’s most efficient and sustainable value chain for seafood by 2025, and aim to avoid harmful impacts on species caused by intervention in the natural environment and in fjord systems, including sedimentation/seabed’s.

We aim to fish and produce food without negatively affecting biodiversity.

Throughout the year, we have meetings, email correspondence and conversations with various stakeholders where we have presentations and discussions related to the areas where we have or can have a potential impact. We also attend conferences and meetings where we meet and discuss. Through this form of dialogue, we gain insight into what stakeholders are concerned with and feedback on what they think about the way we work, measures we have initiated and what they think we should focus on going forward. Through various forms of benchmark surveys, we also receive feedback on what stakeholders think about our measures and their implementation.

Part of our efforts to minimise infection pressure and environmental impact is to have a period of minimum two months every second year during which an individual facility is fallow, cleaned and disinfected. The facilities are divided into zones to allow for coordination of fallow periods. In 2022, each facility was in fallow for 236 days on average.

Feed control is a major part of the efforts to prevent overload. Each cage is fitted with two cameras to monitor the feeding process, so that feeding is stopped when the fish are no longer eating. Dedicated and specialised operators monitor this process continuously. Operators also monitor the number of fish, growth and feed factor to ensure full knowledge at all times of how much the fish in a cage are expected to consume.

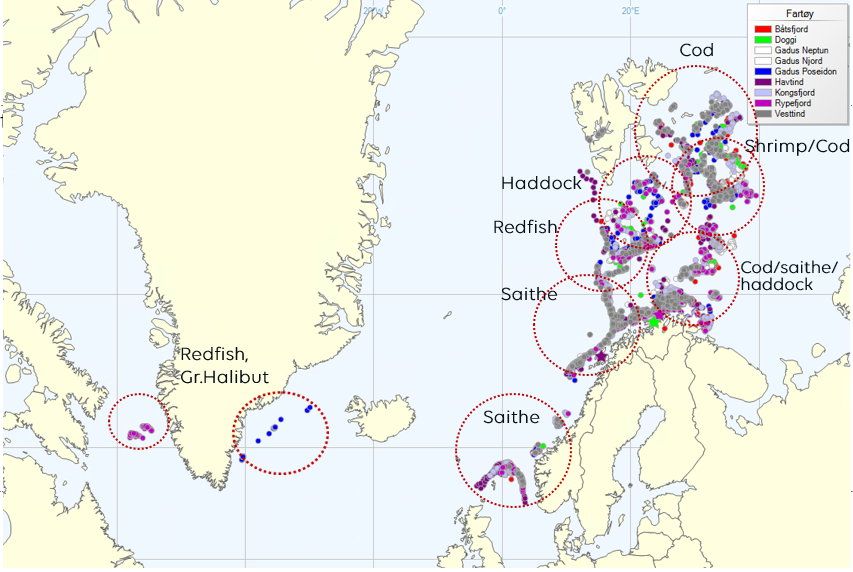

Each year, quotas are allocated for various species that are caught. We mainly fish cod, pollock, haddock and prawns. Everything caught must be brought ashore for inspection. In this way, we ensure that we do not overfish allocated quotas, thereby maintaining the species. We may experience unintentional by-catches. These are managed, recorded, reported and delivered to shore.

Trawling takes place in separate areas to ensure species diversity in the best possible way. The equipment used is also adapted to the operation so that the fishing can be carried out as optimally as possible. Development work is constantly carried out to further develop the fishing tools.

Lost fishing gear left on the seabed spoils the sea and destroys seafood caught in it. For the most part lost fishing gear or "ghost fishing" is represented by gill-nets, a fishing gear not used by the Lerøy Havfisk fleet. Marine fisheries, including Lerøy Havfisk, are required by the Exercise Regulations to report lost gear to the Norwegian Coast Guard-

MOM B and MOM C assessment

Share of facilities in coordinated fallow zone (%)

Average fallow period (number of days)

Escapes ( number)

Percentage of certified marine species caught

Compliance with quotas

On the basis of results from the MOM B surveys, measures are implemented where this is necessary. There may be reduced production for a period, fallowing, relocation of a site, etc.

The Group carries out targeted efforts to shorten production time in the sea by producing large smolt using RAS technology.

In 2013, Ocean Forest was founded together with the environmental organisation, Bellona. Ocean Forest follows a strategy to achieve more efficient recycling of the unexploited resources in the environments surrounding fish farms. This involves utilisation of waste products from fish production to produce species at a lower level in the food chain.

Macroalgae and microalgae require nutrient salts to grow, and nutrient salts are a waste product from e.g., fish farming. Shells live off microalgae and other particles in the sea. This allows for more efficient recycling of unexploited resources in the environments surrounding fish farms while at the same time increasing our marine biomass production without having to add more feed or fertiliser and while keeping our seas cleaner.

The Group invests a considerable amount of resources in optimizing equipment and routines specifically to avoid accidental release of fish.

We operate in areas where wild populations of Atlantic salmon also exists, and release of farmed salmon could interfere with the genetics of local populations

Escape incidents can cause Lerøy financial consequences in the form of fines, reduced income and, in the worst case, a lack of capital. Repeated escape incidents could also affect the company's reputation. Fish from aquaculture that escape can find their way into the rivers where wild salmon stocks live. This can create a risk of affecting species diversity in the rivers. There will be a very low risk of any organic or inorganic impact on environmental conditions. Escaped fish from our company will have very little impact on people or human rights.

Lerøy Seafood Group has a vision of zero escapees.

Significant measures have been implemented to prevent escape at LSG's farming localities. The Group has invested heavily in both technology, control systems and development of new routines to prevent escape.

All Lerøy's facilities comply with technical standard NS 9415:2009 Marine fish farms. These requirements are specified in the NYTEK regulation that governs marine fish farms, all main components, structural elements for mooring and extra equipment.

Actual incidents of accidental release triggers measures determined in the contingency plan and are reported to the Directorate of Fisheries, as are events that may lead to accidental release.

Norwegian Directorate of Fisheries and published on the following website. https://www.fiskeridir.no/Akvakultur/Tall-og-analyse/Roemmingsstatistikk.

Research has shown that escaped fish from aquaculture can have a negative impact on wild salmon that live in rivers in Norway. The Norwegian Institute of Marine Research and various interest organizations monitor wild salmon and publish reports showing the status of the various species of wild salmon.

The national impact of escape of farmed salmon in watercourses is also measured by different projects like: The national monitoring programme for farmed salmon escapees in watercourses.

Lerøy follows developments closely and does our utmost every day to ensure that fish do not escape from our locations.

The Group controls the number of fish in cages at each facility. The number of fish released to each sea cage from the smolt facility is counted according to the number of vaccinations minus dead fish prior to release. All fish that is taken out of the cage after release are logged daily. When an unknown number of fish escape from the cage, a well boat is used to count the remaining fish, and by comparing the well boat count with the marine farm's own figures an estimate of the number of escapees is made.

Target 2023: Zero escape

|

|

2022 |

2021 |

2020 |

2019 |

|

Escapees ( number of fish) |

10 544 |

4 |

208 |

85 |

| Date | Amount of fish escaped | What happend? | Company | Location | Estimated cost |

| 14.05.2023 | 1560 | Hole in groove | Lerøy Sjøtroll | Ramsvik | 1 443 000 |

| 18.07.2023 | 8976 | During smolt reception, it was discovered that the well boat had not closed the inspection hatch. Because of this, smolt was pumped into the sea. Unloading was stopped immediately and recapture nets were deployed | Lerøy Midt | Bogen | 1 125 000 |

| 09.08.2023 | 1 | During lice counting, a fish was lost in the sea | Lerøy Midt | Ringholmen | 500 000 |

| 09.08.2023 | 1 | A fish escaped when testing new equipment | Lerøy Sjøtroll | Rongøy | 500 000 |

| 09.11.2023 | 1 | During lice counting, a fish was lost in the sea | Lerøy Aurora | Tussøy | 500 000 |

| 21.11.2023 | 5 | During lice counting, fish was lost in the sea | Lerøy Midt | Gunnarøya | 2 500 000 |

| 10544 | 6 568 000 |

In 2022, Lerøy had 1 escape incident at Lerøy Sjøtroll where 1,560 fish escaped, and 4 incidents in connection with lice counting where totally 8 fish escaped into the sea.

In addition, Lerøy Midt was involved in an incident where a well boat was the cause of an escape incident where 8,976 fish escaped. The well boat has taken the full responsibility for this incident.

Improvements have been made to secure use of safety measures when capturing fish for delousing and when returning fish to the cage after counting sea lice, to minimise possible escape.

Lerøy has collaborated with other businesses to establish a new company, Sporbarhet AS. The aim is to ensure efficient traceability services for salmon in order to prevent escapees with no known origin. The tracking services currently being developed are based on genotyping of all male fish used for breeding and further element analyses to distinguish between fish with the same genetic origins.

We have implemented the NYTEK standard (minimum technical requirement) and we continuously work together with our suppliers to improve and develop new and better equipment. This is to ensure that all our farms have access to equipment of the highest possible technical standards.

Risk analysis and a number of written procedures helps us operate our farms safely, including to prevent escapes. Among other spesific measures, we regularly check the technical condition of moorings, facilities, vessels and equipment, we use divers and ROVs to check pen farming nets and employees are trained in prevention of escapes.

Before stocking a production site, approval is required from a number of official and private bodies. Furthermore, approval requires compliance with numerous analyses, requirements and local conditions. These approvals are given after mapping and compliance of ecological status, spawning areas for marine species, diversity, and presence of endangered species in the region.

Before stocking a production site, approval is required from a number of official and private bodies. Furthermore, approval requires compliance with numerous analyses, requirements and local conditions. These approvals are given after mapping and compliance of ecological status, spawning areas for marine species, diversity, and presence of endangered species in the region.

One of the assessments carried out both prior to approval for operations at a location and during fish farming at the facility is a MOM-B evaluation.

MOM-B stands for:

M – matfiskanlegg (production facility)

O – overvåkning (monitoring)

M – modellering (modelling)

A MOM-B evaluation is carried out by an independent third party body and involves extraction of samples from the seabed under and close to the cages in a facility.

The analysis has three components:

The MOM B analyses are investigations of grab samples that are collected evenly distributed under the bottom of the fish farm.

All parameters are allocated a score depending of how much the sea bed is affected by the organic substance. The distinction between acceptable and unacceptable sediment condition is set to the highest accumulation that allows burrowing benthic organisms to live in the sediment.

On the basis of these investigations, the individual location receives a score, which also provides an indication of when the next MOM-B investigation should be carried out. Scoring is given from 1- 4 on each parameter on each grab scoop, where 1 is the best result. The total score is the average value of all parameters and grab scoops. If the score is 3 or 4, measures must be taken to improve the condition of the facility.

A poor score often requires more frequent seabed investigations than a good score. In addition to MOM-B, analyses are also conducted locally at individual facilities. These include measurement of density, oxygen level in the sea, currents, water quality, visibility, dives etc.

Each facility is also linked with neighboring facilities in a zone-based cooperation to work together on topics such as lice and preventing accidental release, prevent spread of disease, prevent outbreaks of disease etc.

Average MOM-B max 1.5 per location (average score all surveys in calendar year for locations in operation that year)

KPI 2023: MOM-B score within 1 or 2 for all locations

|

2022 |

2021 |

2020 |

2019 |

|

|

Average MOM B Score |

1,38 |

1,49 |

1,37 |

1,55 |

The Group also conduct MOM C surveys. The C-survey is a trend monitoring of the bottom conditions in the transition zones from the farming zone and outwards in the recipient. This study is based on mapping of fauna on soft bottoms, which is carried out in accordance with relevant ISO standards.

In addition, hydrographic, geological and chemical support parameters are included. These extended trend monitoring outside the local areas is done as often as required, depending of environmental conditions, standard criteria and permit terms.

All fish farms in use are regularly monitored using regular monitoring programs. MOM B and / or MOM C environmental surveys are carried out at least annually in the near zone at each fish farm in connection with biomass peaks / maximum production capacity. These surveys are carried out in accordance with NS 9410 and are based on the Aquaculture Operations Regulations.

A pilot project has been initiated at a marine locality with commercial operations for collection of mud. The objective with this project is to minimise the carbon footprint on the seabed under the facility. This is the first trial involving collection of mud from commercial, full-scale marine facilities.

The project has the potential to contribute to development of new technology for collection in traditional facilities with an open cage system. The project is being conducted in collaboration with STIM, and is partly financed by Innovation Norway.

Copper is a naturally occurring chemical element which can be toxic at high levels in the marine environment. Nets can be treated with antifouling agents containing copper. Also, cleaning of nets during the production cycle is necessary to ensure good water quality for the farmed fish. Lerøy Seafood Group uses low-pressure underwater washers to reduse copper release to the environment.

Together with suppliers, the Group works to identify alternative antifouling products and alternative net materials. Such alternative solutions are now in our “tool-box” for managing nets, and are implemented in the Group´s production strategies.

In addition to cleaning in-situ, all nets are cleaned at onshore sites after each production period. Onshore cleaning sites have zero copper emissions, as required by Norwegian legislation.

Replace antifouling agents that contain copper

As a strategy to minimize infection pressure and environmental impact, all sites are fallowed and washed/disinfected every two years. In all regions where the Group has operations, fallowing and stocking periods are coordinated in zones, defined by the The Norwegian Food Safety Authority, NFSA and companies in each Area Based Management, ABM scheme.

Every site in a defined coordinated area is fallowed every second year for at least two months. Within each area-based management area, there is at least a one-month coordinated fallowing period every second year.

In 2022, every marine site in the Group was fallowed for 236 days on average.

|

2022 |

2021 |

2020 |

2019 |

|

|

Average number of days fallow per locality: |

236 |

142 |

138 |

140 |

Average fallowing per location: Minimum 60 days

The maximum legislative limit for fish density in a seacage is 25 kg/m3. Average density in the Group´s cages is far below this, indicating that the fish have plenty of space in the cages. In 2021, the average density for the Group´s seafarms was 8,7 kg/m3.

Fish health and fish welfare are at the core of our operations as a producer of Atlantic salmon and rainbow trout. As such, we are committed to both ethical and statutory obligations governed by Norwegian legislation.

A healthy fish is also a good fish for production and a prerequisite for good financial results. There are therefore numerous incentives for putting fish health and fish welfare at the top of the agenda for fish-farming operations. In an effort to ensure that we continuously fulfill these obligations, the Group has chosen to invest substantial resources in preventive measures for fish health, and this is a major part of the production strategy for the entire Group.

MAIN GOAL DENSITY: Less than 25 kg/m3

|

2022 |

2021 |

2020 |

2019 |

|

|

Average density all locations: |

8,0 |

8,7 |

8,4 |

8,8 |

We care about the welfare of our fish and accept our ethical responsibility that comes with animal farming. The Group's goal is qualitative and requires continuous monitoring and targeted efforts throughout our farming value chain.

Sustainable management is central to the Norwegian fishing industry, and includes biological, social and economic sustainability. Biological sustainability means that marine resources, such as fish stocks, must be utilized in a way that allows them to continue fishing into the future. This is managed by means of quotas to avoid overfishing, and these are based on stock surveys that are done every year. Social sustainability is about the distribution of resources between different actors, such as the coastal and ocean-going fleets, or between different regions along the coast. Economic sustainability means that fishing is economically profitable, so that fishermen earn enough to live, and that the nation of Norway earns from exporting seafood

Advice and recommendations from ICES form the main basis for setting fishing quotas. Researchers from the member countries prepare the various councils in groups and advisory committees. After ICES has come up with its quota recommendations, it starts negotiations between Norway and other states. When the international negotiations are completed, start the national regulatory processing process. The Directorate of Fisheries makes proposals to the national

the regulation.

Norway is a member of five regional fisheries management organizations (RFMOs). These are the Northeast Atlantic Fisheries Commission (NEAFC) and the Northwest Atlantic the Fisheries Organization (NAFO). Norway is also a member of the Southeast Atlantic Fisheries Organization (SEAFO), the International Commission for the Conservation of Atlantic Tuna (ICCAT) and the Convention of the Conservation of Antarctic Living Marine Resources (CCAMLR).

We depend on sustainable management of marine natural resources and maintenance of clean and productive marine areas. In our main operating area, more than 90% of all Norwegian wild fish landed annually are certified as sustainable according to MSC-certified sustainable fisheries. Main catch species for Lerøy Havfisk is cod, haddoch, saith and shrimp caught in the North Sea, Norwegian Sea and Barents Sea (FAO27)

Research and advice from the Institute of Marine Research in Bergen and the International Council for the Exploration of the Sea (ICES) shall help ensure that future generations are able to harvest the major assets in the sea and along the coast.

One of the vessels owned by our subsidiary Lerøy Havfisk is part of the Institute of Marine Research's reference fleet. As such, we play a part in collecting a significant amount of biological data utilised in the research into fish stocks. Norway enters into negotiations with other countries when total fishing quotas are to be established. The final decisions regarding the total quotas for fishing different species are made on the basis of stock assessments and advice on quotas from ICES.

More than 90% of the fish resources harvested by Norway are managed in cooperation with other countries. The national quotas in Norway are discussed by the various stakeholders during regulation meetings, for which the Norwegian Directorate of Fisheries is responsible. These regulation meetings are held twice a year.

Subsequent to the discussions at these meetings, the Directorate of Fisheries issues a proposal for regulation of fisheries to the Norwegian Ministry of Trade, Industry and Fisheries. The Ministry issues provisions regarding the distribution of quotas to Norwegian fishing vessels and provisions regarding fisheries in the form of annual regulations for each species of fish.

Our operations are based on public permits for the harvesting of Norwegian fish resources. The entitlement provided by these permits entails statutory obligations in terms of activity and delivery, as well as a responsibility to fish sustainably. It is our aim to be a “proud custodian”, and we have taken an active approach to ensuring full compliance with all regulations involving fisheries.

We manage our natural resources on behalf of society as a whole, and therefore accept a particular responsibility for ensuring sustainable operations, leaving behind the smallest possible environmental footprint. The Group monitors all employees and management to ensure compliance with prevailing regulations and quota provisions. The Group has also cooperated with authorities, trade associations and nongovernmental organisations to help counteract illegal fishing, thereby safeguarding resources for future generations.

In 2016, Lerøy Havfisk and the other parties involved in the Norwegian trawling industry entered into the Arktisavtalen (Industry Group Agreement on cod fisheries in the northern part of the North-East Atlantic). As a result of the melting ice sheet around the North Pole and so-called new areas becoming accessible, a map has been prepared showing those regions traditionally fished.

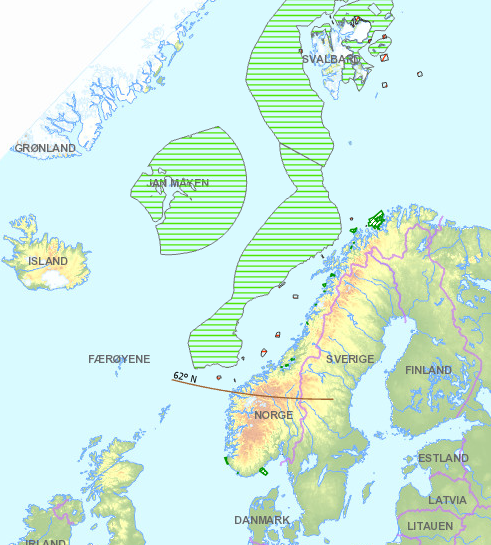

The parties to the agreement committed to not fish in waters north of these areas until the seabed had been charted andit had been established that fishing would not cause permanent damage to vulnerable benthic biotopes. In 2019 this agreement was replaced with new Norwegian government regulations to the same effect.

The regulations were implemented following open dialog between Government, industry and NGOs. In addition to the vast areas protected under the new regulations, there are 19 areas along coastal Norway that are protected against bottom trawling to protect coral and other benthic organisms. Additionally, trawlers are not allowed to fish inside of 12 nautical miles along the entire Norwegian coast, with the exception of small trawlers that have a 6 mile limit. Around all of the Svalbard islands there is a 12 mile limit.

Areas protected in the Norwegian economic zone Source: The Norwegian Fishery Directory

Combined with a more comprehensive nature reserve where fishing is prohibited and a general prohibition on fishing in waters that are shallower than 100 metres around Svalbard, the protected area covers 70.000 square kilometres, not including all before mentioned new protected areas.

The minimum water depth of 100 metres protects food sources for animals that live on shore and birds that dive for food close to the coast. A number of other regulatory measures also apply,including a prohibition on fishing deeper than 1.000 metres to protect potentially vulnerable benthic biotopes in these areas.

Lost fishing equipment leads to marine litter, which in turn entails a risk of ghost fishing

Parts of the fishing gear used by Lerøy Havfisk consist of plastic and plastic components. Lost fishing gear left on the seabed spoils the sea and cause death of wildlife caught in it through exhaustion and suffocation. Ever since the early 1980s, the Directorate of Fisheries has carried out annual clean-ups along the Norwegian coastline, to remove fishing gear from the seabed – an important measure to avoid fish and shellfish getting caught, or "ghost fishing" as it is called. Furthermore, this represents general marine pollution.

Read more: Ghost fishing

For the most part lost fishing gear or "ghost fishing" is represented by gill-nets, a fishing gear not used by the Lerøy Havfisk fleet. Fortunately, it is not often that Lerøy Havfisk loses its fishing gear, but it has happened. Marine fisheries, including Lerøy Havfisk, are required by the Exercise Regulations to report lost gear to the Norwegian Coast Guard, and in recent years reporting has been further simplified through functions in the electronic catch log.

Lerøy Havfisk will continue to spend time searching for any lost fishing gear, and we most often succeed in finding and recovering lost fishing gear. This in turn represents reduced consumption, and will at all times be included as part of the company's action plan for reduced plastic consumption (provided that fisheries, ropes, etc. contain plastic and plastic components).

In addition to production of Lump Sucker, the Group also buys wrasse from local fishermen. As part of our sustainability efforts, we have decided to demand two things from fishermen who supply Lump Sucker to us.

As a general rule, our activities shall not impact on any other species or protected habitats. We only fish species that are properly managed and seek to use the equipment that is best for different species and habitats at all times. Despite this, we may experience unintentional by-catches. These are managed, recorded, reported and delivered to shore.

In aquaculture, we take a special responsibility for wild salmon as it lives naturally in Norwegian rivers. We participate in various interest groups working to safeguard the wild salmon in Norway.

Our different sites have a predator management system and keep records and report risk events, e.g., net holes, infrastructure issues, handling errors, reporting and follow up of escape events.